Welcome to the High Temperature Thermal Analysis Laboratory (HTTAL) webpages!

We are a group of materials engineers and scientists at Dalhousie University who have interests and expertise in developing new materials and processes, optimizing existing manufacturing methods, and understanding processing-microstructure-property relationships.

Based on this description, you might be asking yourself,

The core of our unique approach is the application of a wide range of high temperature thermal analysis techniques to solve Materials Science and Engineering problems.

Equipment

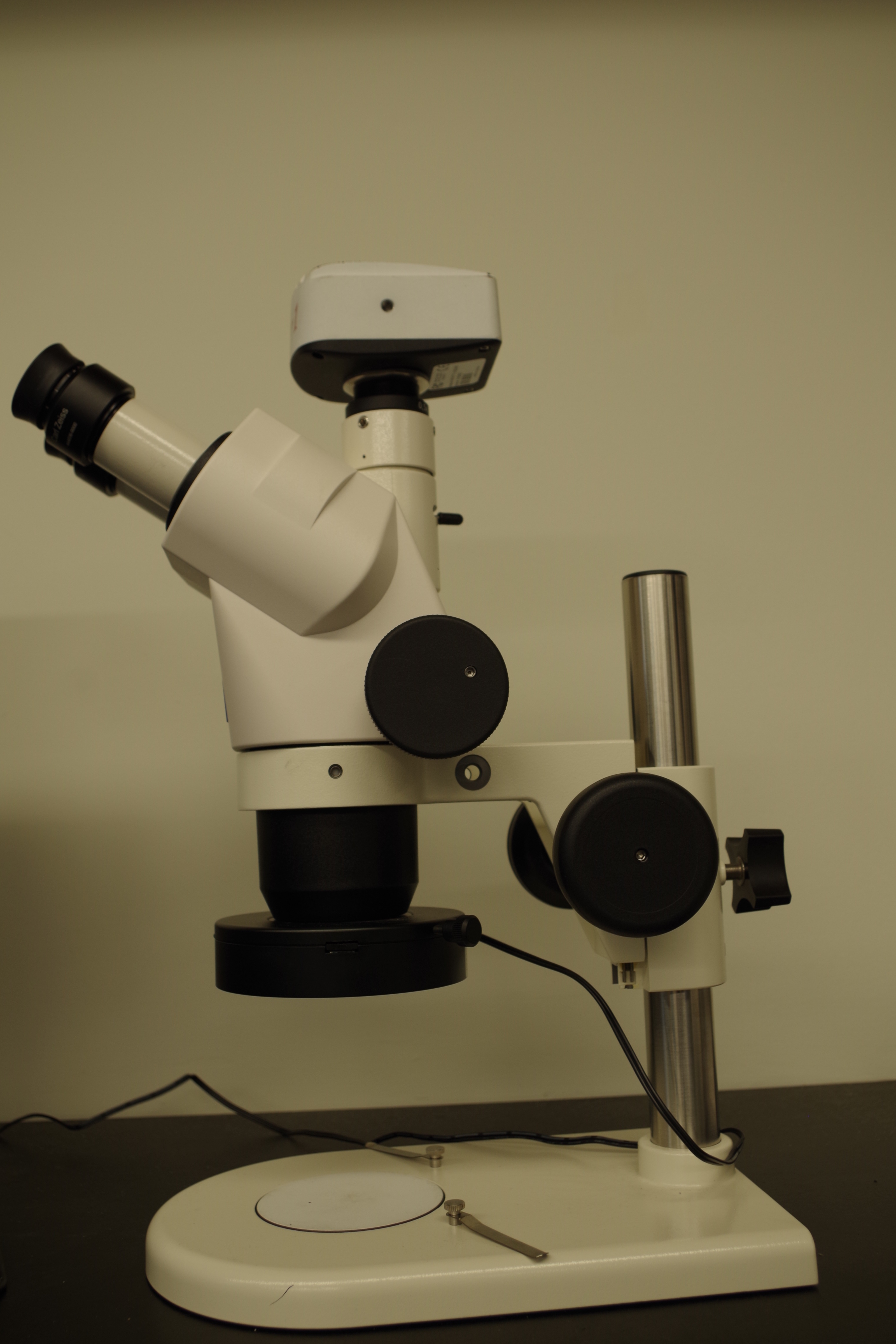

See the list of Equipment available in the HTTAL! Capabilities include: thermal analysis, microstructural analysis, and powder compaction.